Exercise 7: Bill of Materials

Reference Material

Bill of Materials

Exercise Objectives

Part 1: Assign a Kit to the Batch

Part 2: Add an inventory field to a Step

Part 3: Configure inventory fields to only use Items in a Kit

Part 4: Create a new Batch Record in MES to test these changes

Scenario

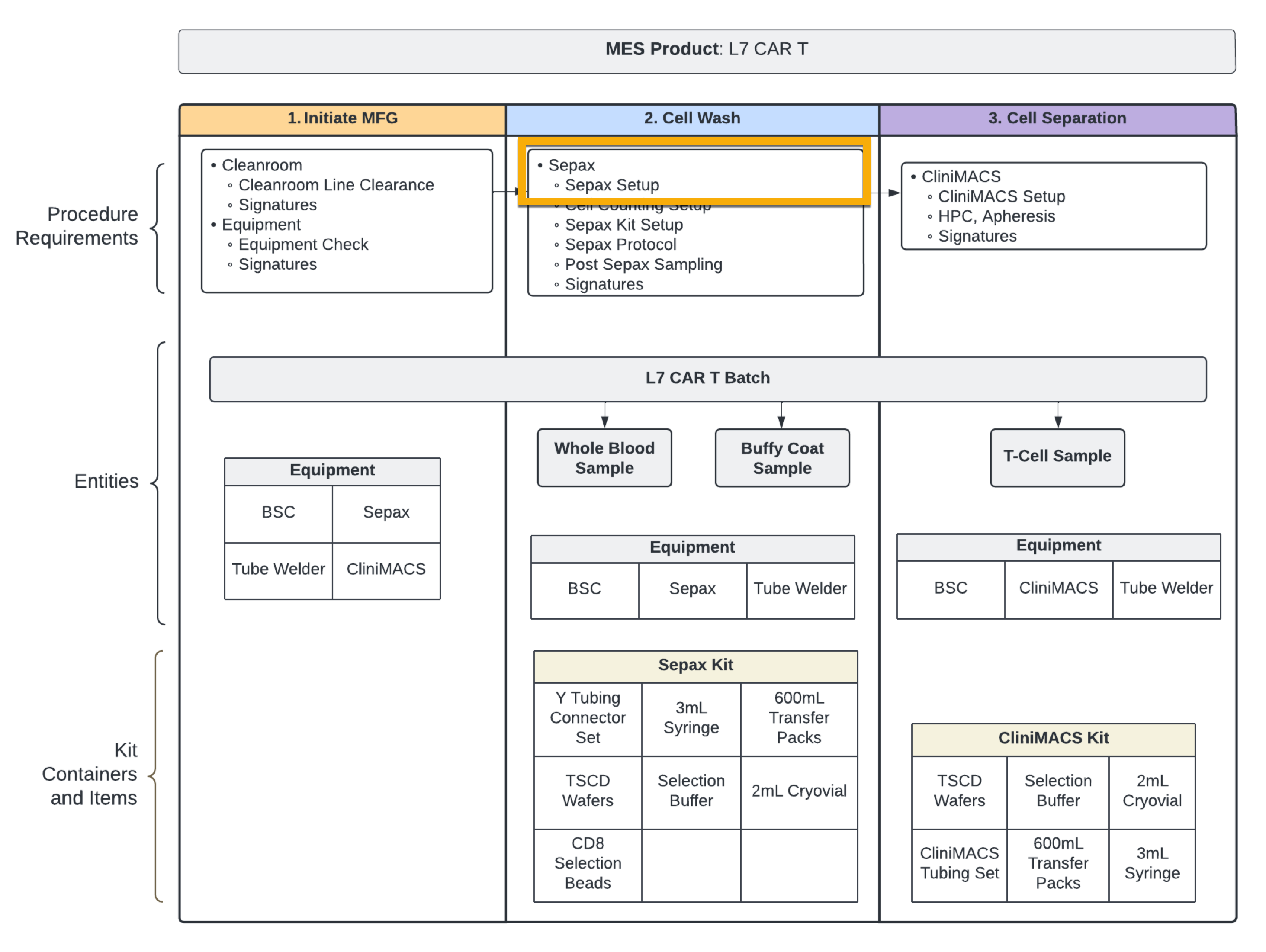

In manufacturing, kits are assigned to a Batch and consumed during production. Kit assignments can be made during Batch creation or Batch production. In CAR T Processing, the Sepax and CliniMACS Kits are assigned during Batch production.

Your Task

Part 1: Add a field to the Sepax Step that assigns a Sepax Kit to the Batch.

Manufacturing Operations has provided the following requirements:

Position: immediately downstream of the

Tube WelderfieldName: Sepax Kit

Sub-Step: Sepax Setup

Instructions: Verify that the assigned kit is being used in production. If not, update the selection below and save the Batch Record.

Tip

What HTML element will bold text? Review our HTML guide here

Warning

Do not restrict Containers by status or update this status after use.

Part 2: Add two (2) fields to the Sepax Step for consumption of the following inventory items:

Y Tubing Connector Set

Position: immediately downstream of the

Sepax Kitfield created in Part 1Name: Y Tubing Connector Set

Sub-Step: Sepax Setup

Sub-Step table: Inventory

Valid Item Status:

Verified

CD8 Selection Beads

Position: immediately downstream of the

TSCD WaftersfieldName: CD8 Selection Beads

Sub-Step: Sepax Setup

Sub-Step table: Inventory

Valid Item Status:

Verified

Tip

When creating Sub-Step tables and restricting Items to kits, consider:

How do you add a field to a Sub-Step table using a Var Group?

What L7|ESP Expression will restrict Items to the Sepax Kit selected during Batch production?

Part 3: Restrict the other Items in the Inventory Sub-Step table using the same L7|ESP Expression.

Part 4: Create a new Batch Record for CAR T Processing to confirm that these requirements were modeled correctly.