Change Request - Process Models

As a group, read through the following Change Request and see how it translates to the requirements documented in your shared Google Sheet.

Important

Timing: You have 90 minutes to complete this stage of the project, after which we will debrief as a group.

Note

Build the Perform and Observe Signature Flow before using it in the Xuri Step. Signature Flow requirements are provided at the bottom of this page.

Recipe: CAR T Processing

Create a copy of the

CAR T ProcessingRecipeRename the Recipe

CAR T Processing and ExpansionAdd the

Cell ExpansionSection to the endPlace this Section in a new swim lane named

ExpansionThe Batch will transition to this Section when Cell Separation has been completed

Create a new

CAR TProduct in the MESProduct appMES Process:

CAR T Processing and ExpansionProduct Name:

CD22 CAR T

Section: Cell Expansion

Add instructions that link to vendor documentation for the CellBag and Cell Expansion System. The formatted Procedures are shown below:

CellBag Instructions - hyperlink to the file with the same name in the Data app

Video Demonstration - https://www.youtube.com/watch?v=39p6IDI39so&ab_channel=Cytiva

Tip

What HTML element will create the largest heading and a line break between hyperlinks?

Review our HTML guide here

Add a data link to pull the

Xuri Kitfrom the CAR T Batch EntityDo the same for the

Sepax KitandCliniMACS Kitin the Cell Wash and Cell Separation Sections

Tip

Commonly used Expressions for Workflow data links.

Expression

Description

{{ cell('Field ID', 'Protocol ID') }}Used to link a value from a field in an upstream Protocol.

{{ cell('Field ID', 'Protocol ID', generation=-1 }}Used to link a value from a field in an upstream Protocol, where the parent of the current Entity is the Entity in that upstream Protocol.

{{ tagged_value(['tag']) }}Used to link a value from a tagged field associated with an Entity or Protocol.

{{ entity_value('Field Name') }}Used to link a value from a field associated with the current Entity in the Protocol.

{{ entity_value('Field Name', generation=-1) }}Used to link a value from a field associated with the Parent of the current Entity in the Protocol.

Important

Testing: Create a new Batch Record in the MES app to test these changes with the CD22 CAR T Product

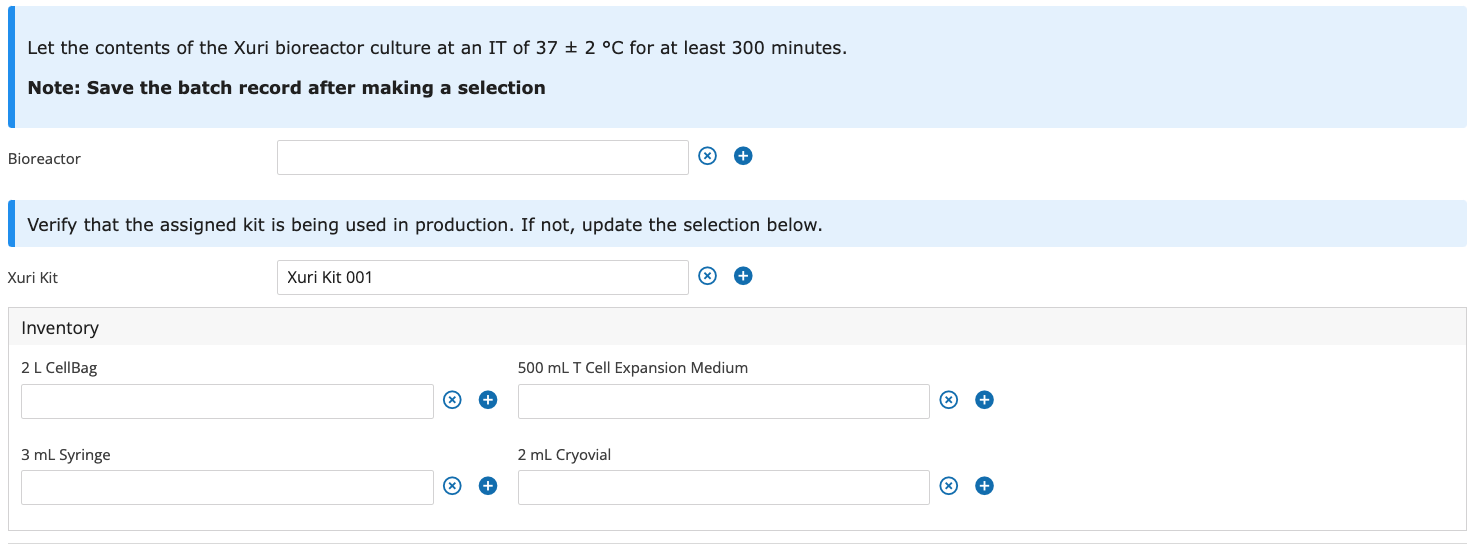

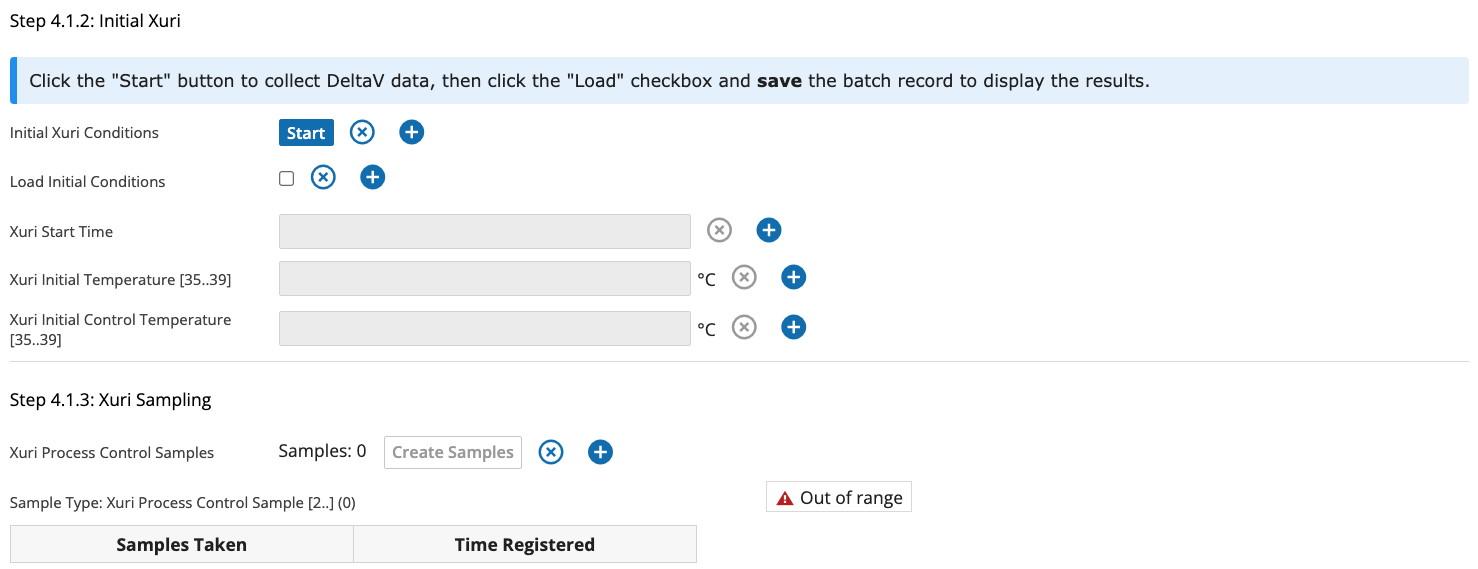

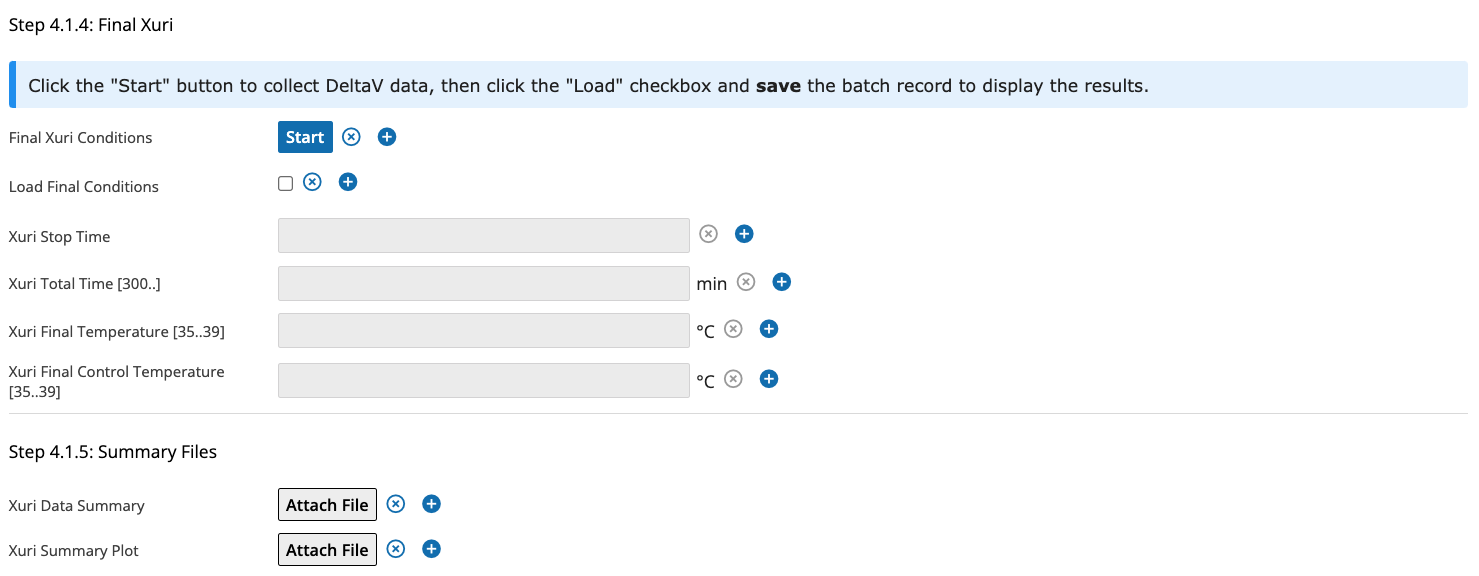

Step: Xuri

In the screenshots below, pay special attention to:

Sub-Steps and Sub-Step tables

Fields that are editable vs. read-only

Sample Types collected at Sample Points, and their min and/or max values

Min and/or max values for numeric fields and their Units of Measure

Restrict the

Xuri Kitfield to kits of this typeAdd two (2) fields for consumption of the following inventory items:

2 L CellBag

Position: immediately downstream of the

Xuri KitfieldName: 2 L CellBag

Sub-Step: Xuri Setup

Sub-Step table: Inventory

Valid Item Status:

Verified

500 mL T Cell Expansion Medium

Position: immediately downstream of the

2 L CellBagfieldName: 500 mL T Cell Expansion Medium

Sub-Step: Xuri Setup

Sub-Step table: Inventory

Valid Item Status:

Verified

Tip

When setting up Sub-Step tables and restricting Items to Kits, consider:

How do you add a field to a Sub-Step table using a Var Group?

What L7|ESP Expression will restrict Items to the Xuri Kit selected during Batch production?

Expression

Description

{{ [json_loads(entity_value('Field Name'))['uuid']] }}Used to reference a Batch Entity Type field.

{{ [json_loads(cell('Field ID', 'Protocol ID'))['uuid']] }}Used to reference a field in a Protocol by

ID{{ [json_loads(tagged_value(['tag']))['uuid']] }}Used to reference a field in a Protocol by

tag

Add a new Sub-Step named

Xuri Samplingwith the following Sample Point:Xuri Process Control Samples

Field position, name, and parameters can be taken from the screenshot below:

Add a numeric field named

Xuri Total Timeto theFinal XuriSub-StepThis field is a Critical Process Parameter (CPP)

Field position, unit of measure, and a min/max value can be taken from the screenshot below:

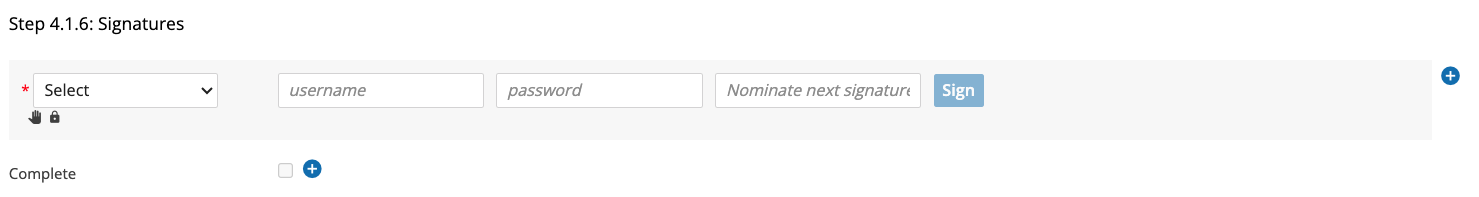

Create a new Signature Flow named Perform and Observe

Perform and Observe

Accept Reasons:

Performed byandObserved byReject Reasons:

ExceptionSignature 1

Signed by members of the

Manufacturing TechnicianRoleBlock progress until signed

Signature locks data

Signature 2

Signed by members of the

Manufacturing TechnicianRoleNominated by the previous signer

Note

The observer does not need to sign if the performer signs first. However, if the performer cannot sign in real-time, the observer must sign first and then nominate the performer.

How does the Signature Flow need to be configured to meet these requirements?

Add a new Sub-Step named

Signaturescontaining the Perform and Observe Signature Flow and Complete field

Important

Testing: Create a new Batch Record in the MES app to test these changes. Pin the CAR T Processing and Expansion Recipe once testing is complete.