Exercise 9: Specifications

Reference Material

Specifications

Exercise Objectives

Part 1: Create two (2) new Spec Types

Part 2: Add Specifications to CAR T Processing

Part 3: Create a new Batch Record in MES to test these changes

Scenario

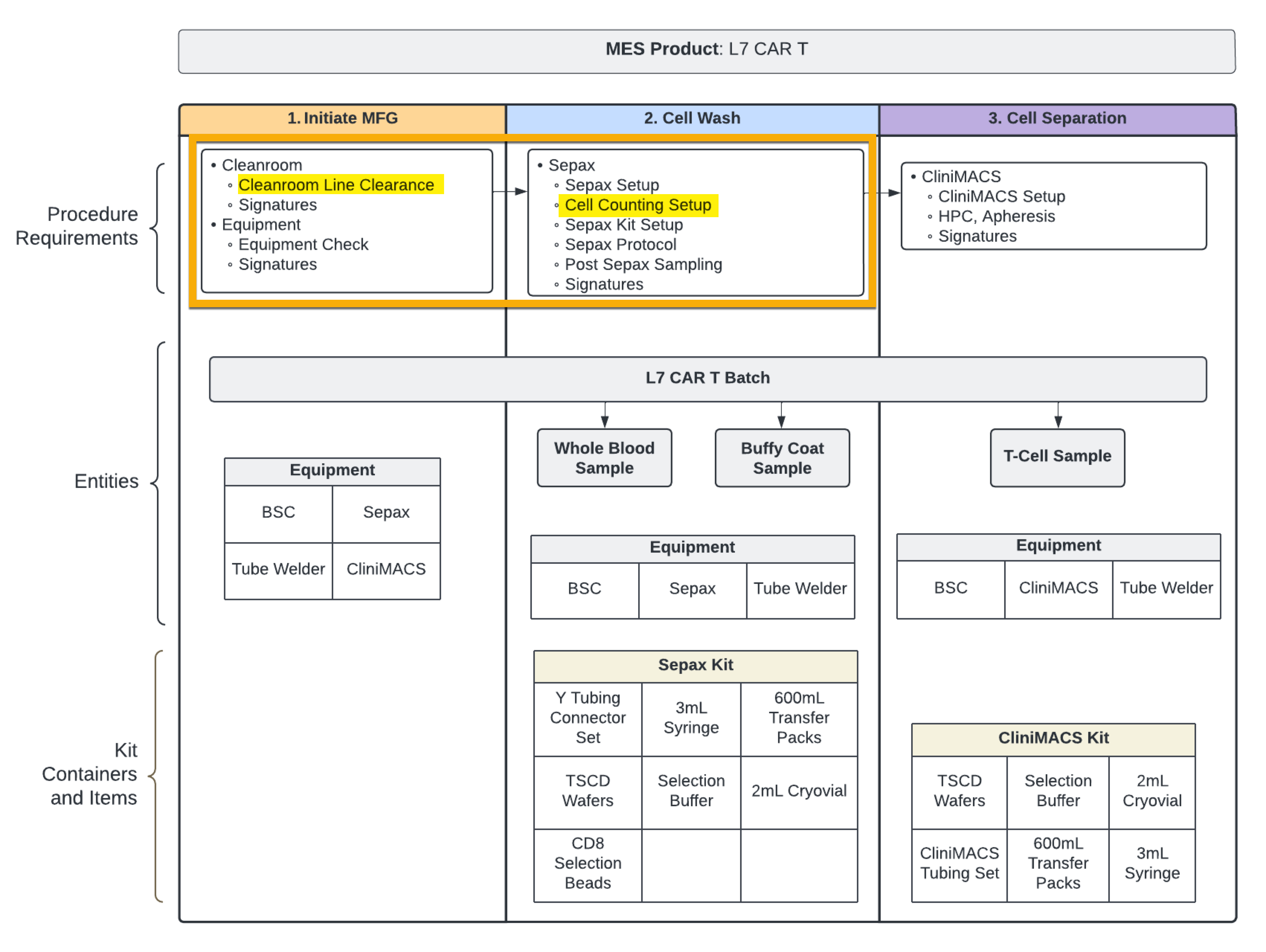

In manufacturing, a number of critical and key process parameters and quality attributes are recorded in the Batch Record. In CAR T Processing, some of these specifications still need to be defined.

Your Task

Part 1: As a Super User, you have been asked to add the following Spec Types:

KPP (Key Process Parameter)

KPI (Key Process Indicator)

Tip

Spec Types are managed in the Configuration app.

Part 2: Add the following Specifications to CAR T Processing:

Cleanroom Line Clearance Sub-Step

Field: Line Clean Duration

Critical Quality Attribute

Measured in

minMust be at least 15

Cell Counting Sub-Step

Field: VCD

Critical Process Parameter

Measured in

x10^5 cells/mLMust be between 1 and 2.5

Field: Viability

Critical Process Parameter

Measured in

%Must be at least 80

Part 3: Create a new Batch Record for CAR T Processing to confirm that these requirements were modeled correctly.

Tip

Questions to consider:

Where is the defined range displayed in the Batch Record?

How do you know if the recorded value is in-range?

Where is the spec type displayed in MES?