Exercise 1: Creating Steps and Sub-Steps

Reference Material

Modeling Steps (Protocols)

Objectives

Part 1: Update an existing Step in the Protocol builder

Part 2: Create a new Batch Record in MES to test these changes

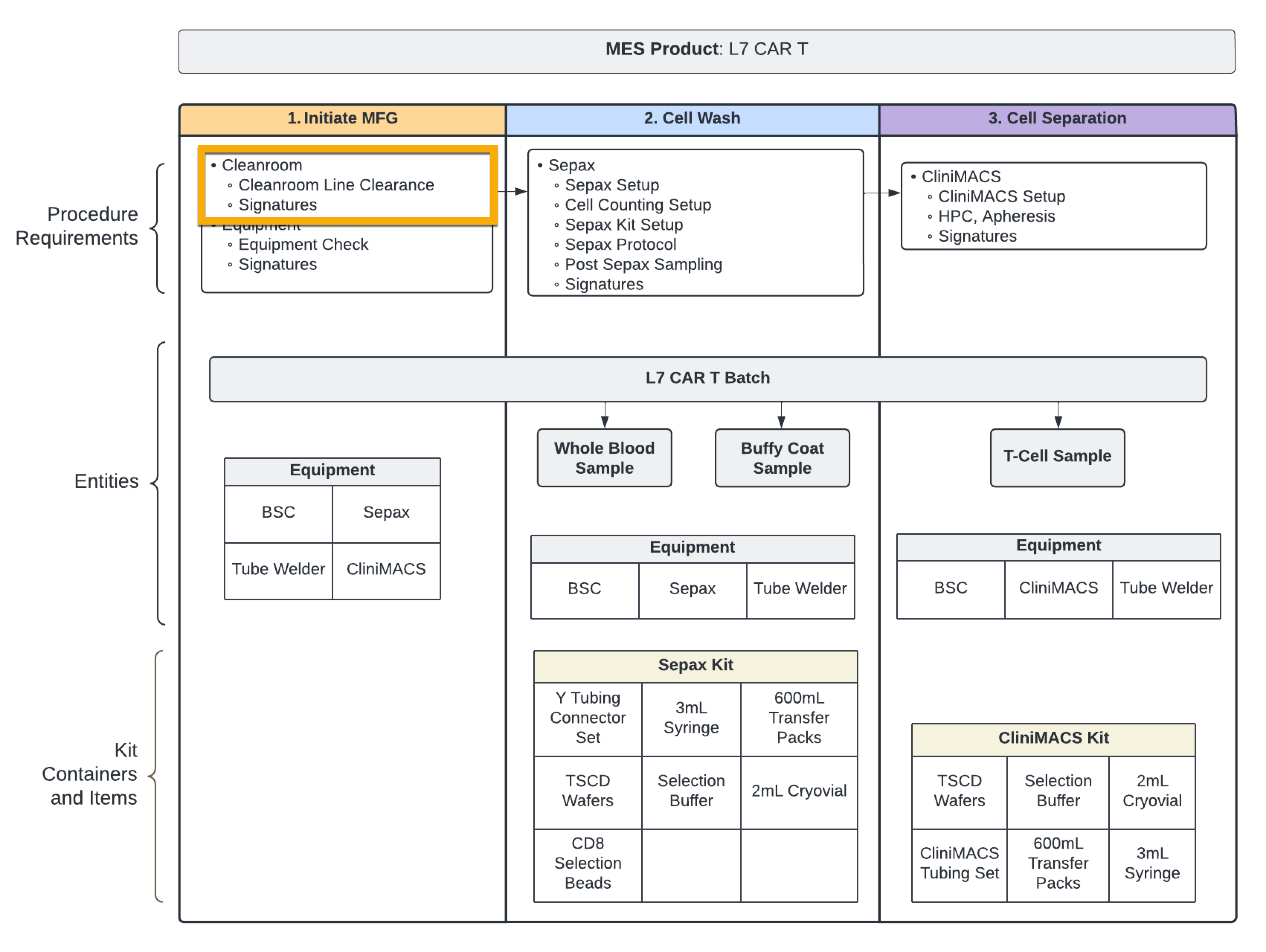

Scenario

Before a product can be manufactured, the manufacturing suite must be cleared and cleaned with a sanitizing agent.

Your Task

Part 1: As a Super User, you have been asked to add Line Clearance activities and instructions to an existing manufacturing process for CAR T-cells.

Manufacturing Operations has provided the following requirements:

Cleanroom Step

Step instructions that read:

Complete the Cleanroom Line Clearance per SOP-5256. Ensure the Line Clearance has been reviewed by QA, and that the room has been released for manufacturing.

Tip

What HTML element will bold text? Review our HTML guide here

New Sub-Step named

Cleanroom Line Clearancewith a Sub-Step Table namedLine ClearanceThis new Sub-Step Table has the following fields:

Line Clearance instructions that read:

Enter the Cleanroom and verify that all previous production materials have been removed. Verify trash liners are empty and free of any residual material or packaging.

Line Clearance Location with the following options:

Cleanroom 1

Cleanroom 2

Line Clearance Date Time in the format

YYYY-MM-DD HH:mm Z

Note

These fields should be the first three (3) fields in the Step.

Part 2: Create a new Batch Record for CAR T Processing to confirm that these requirements were modeled correctly.