Planner

Section Goals

After completing this section, you will:

Understand the role of the Planner

Know how to create Batches

Know how to print Sample labels

Term | Definition |

Batch | Manufacturing run to produce a Product. |

Product | The therapeutic being manufactured. |

Recipe | Manufacturing process to produce a Product. |

Specification Plan | Numeric fields with upper and/or lower limits in the Batch process (Recipe). |

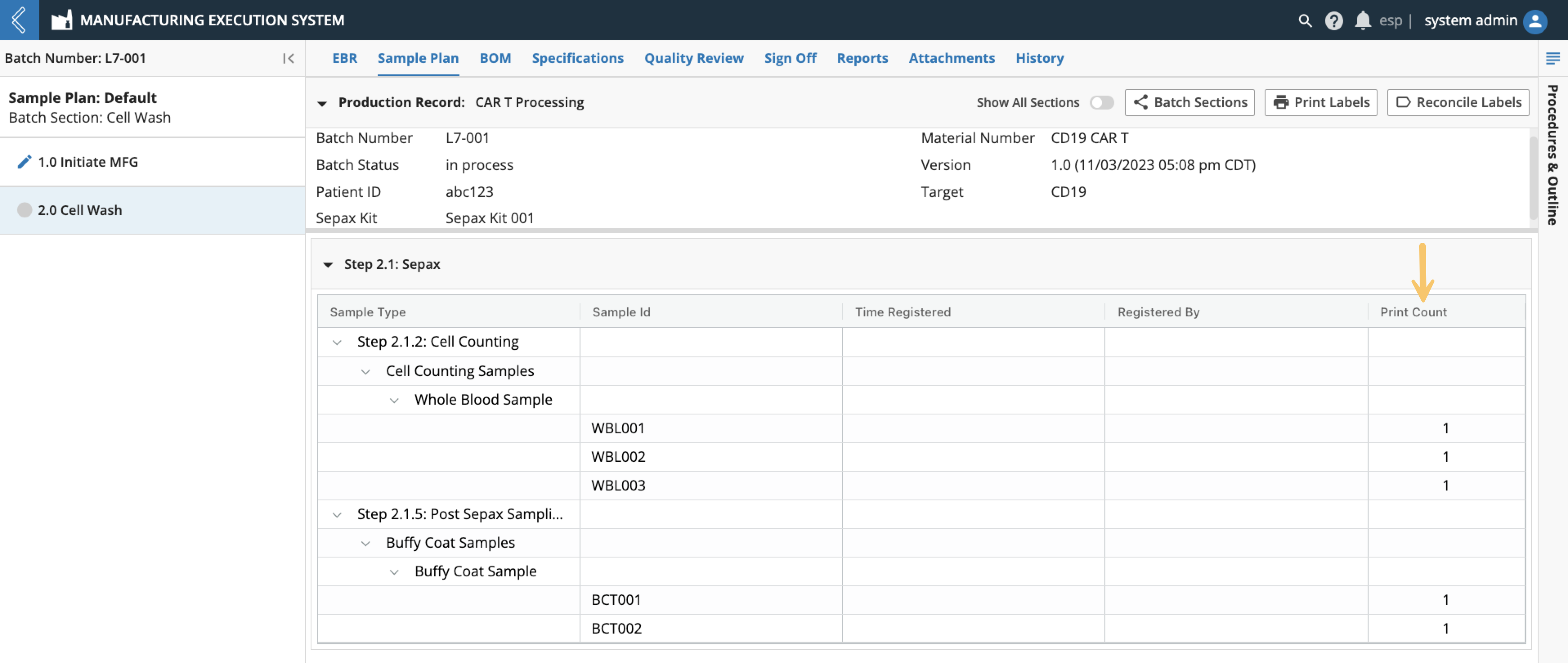

Sample Plan | Number and type of Samples collected in the Batch process (Recipe). |

MES Tab | Activity | Permission(s) |

|---|---|---|

Landing Page | Create Batch | MES → Batch Creation LIMS → Workflow Chain Instance → Create |

Sample Plan | Print labels | MES → Batch Creation Analysis → Pipeline → Execute |

The Planner is responsible for creating Batches and printing Sample labels. To complete these tasks, they use the L7 MES landing page and Sample Plan tab within the Batch Record.

|

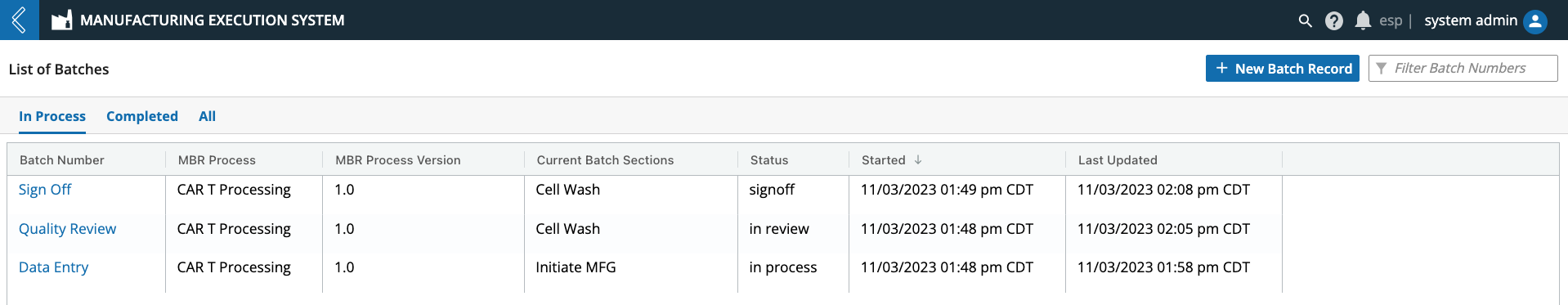

The L7 MES landing page displays all Batches that have been created in L7 MES. To review or work with a Batch, select the relevant Batch Number.

Batches are listed in descending order of their creation date, and organized into three tabs:

In Process – Batches that are currently active (default view)

Completed – Batches that have been completed or failed

All – in-process and completed Batches

All three tabs display the same Batch details:

|

Batch Number – name of the Batch

MBR Process – Recipe used for the Batch

MBR Process Version – Recipe version used for the Batch

Current Batch Sections:

If the Batch is in process, this column lists all active Batch Sections

If the Batch is completed, this column lists the last Batch Section

If the Batch is failed, this column lists the last Batch Section that was active at the time of failure

Status:

In process – data is actively being collected

In review – all Sections and Steps have been completed, but at least one Step requires review

Reviewed – all Sections and Steps have been reviewed, and the Batch is ready for quality review signatures

Sign-off – quality review signatures are complete, and the Batch is ready for final sign-off

Complete – all work for the Batch is complete

Failed – the Batch has been failed

Started – date time the Batch was created

Last Update – last date time any activity was recorded for the Batch

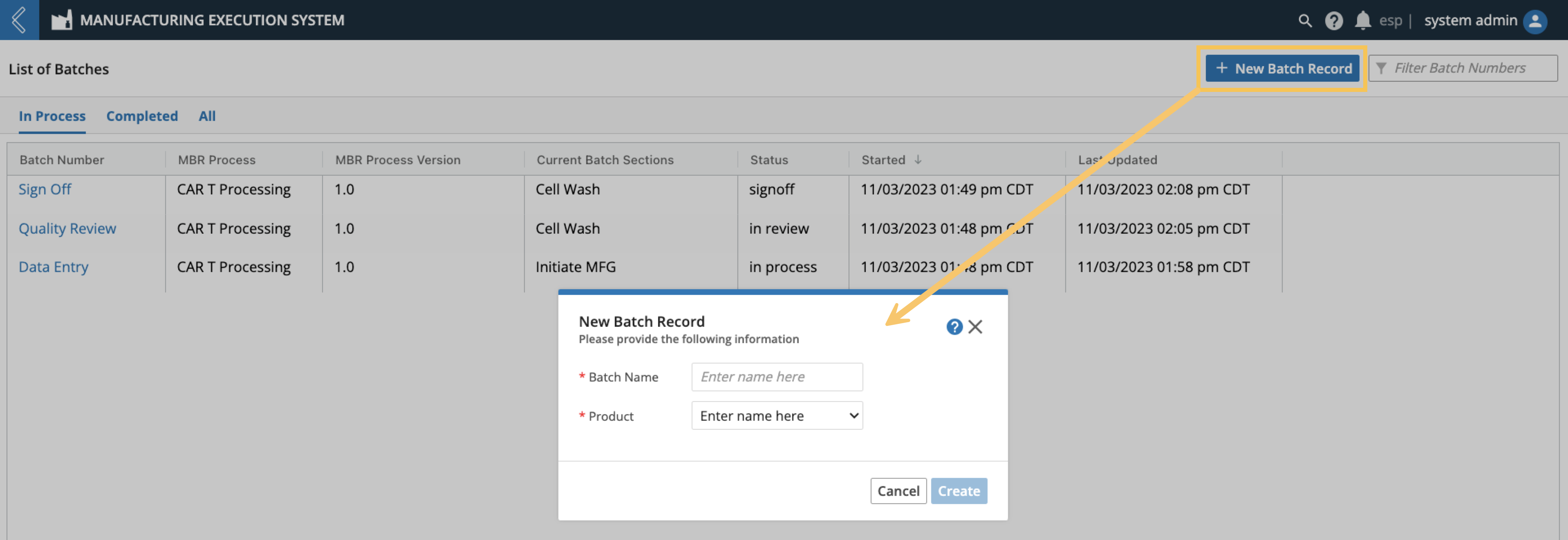

Follow the steps below to create a new Batch.

From the L7 MES landing page, select + New Batch Record

|

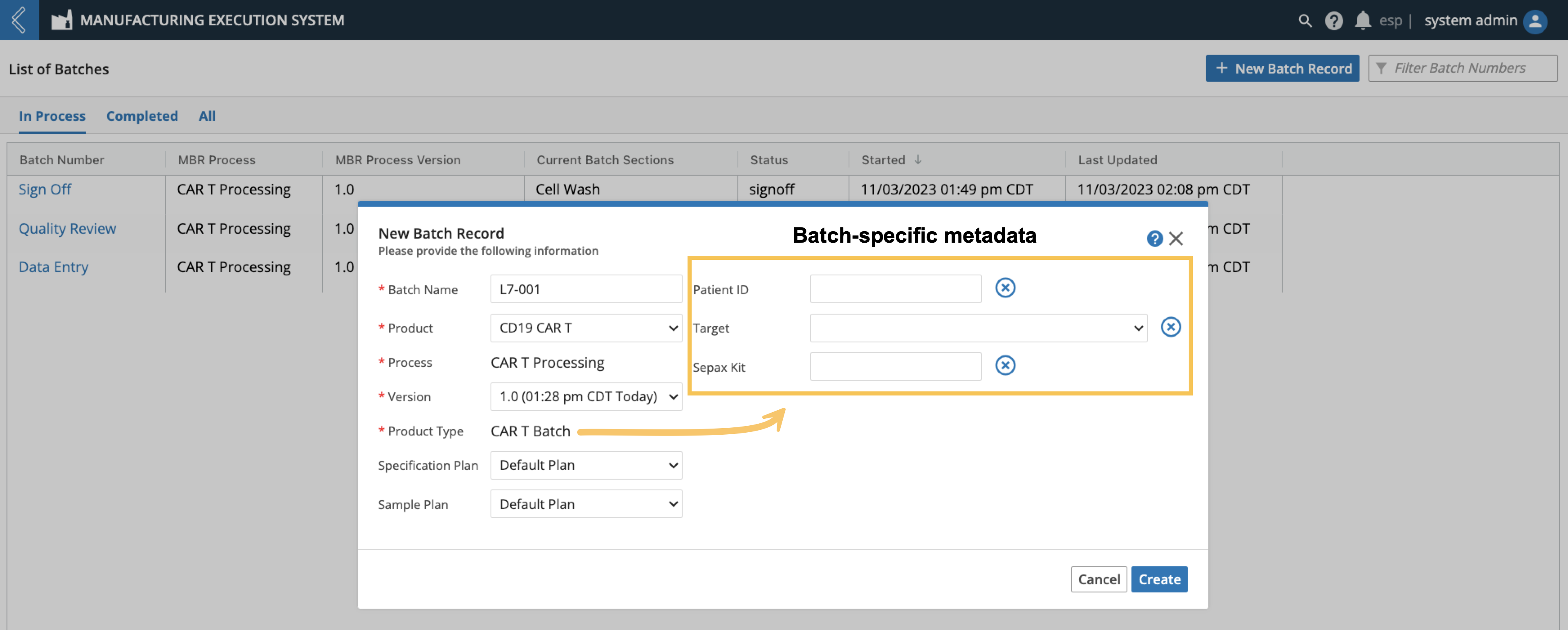

Enter a Batch Name (free-form text)

Select which Product is being manufactured

The Process (Recipe) is auto-populated due to its linkage with the Product

Select which Version of the Process to use

Note

Production environments should only use pinned versions

Select a Specification Plan (optional)

Select a Sample Plan (optional)

Enter any additional Batch-specific information that may be required

Depending on how the manufacturing process has been configured, the Planner may need to enter additional information about the Batch, including Kit assignments.

Click Create

|

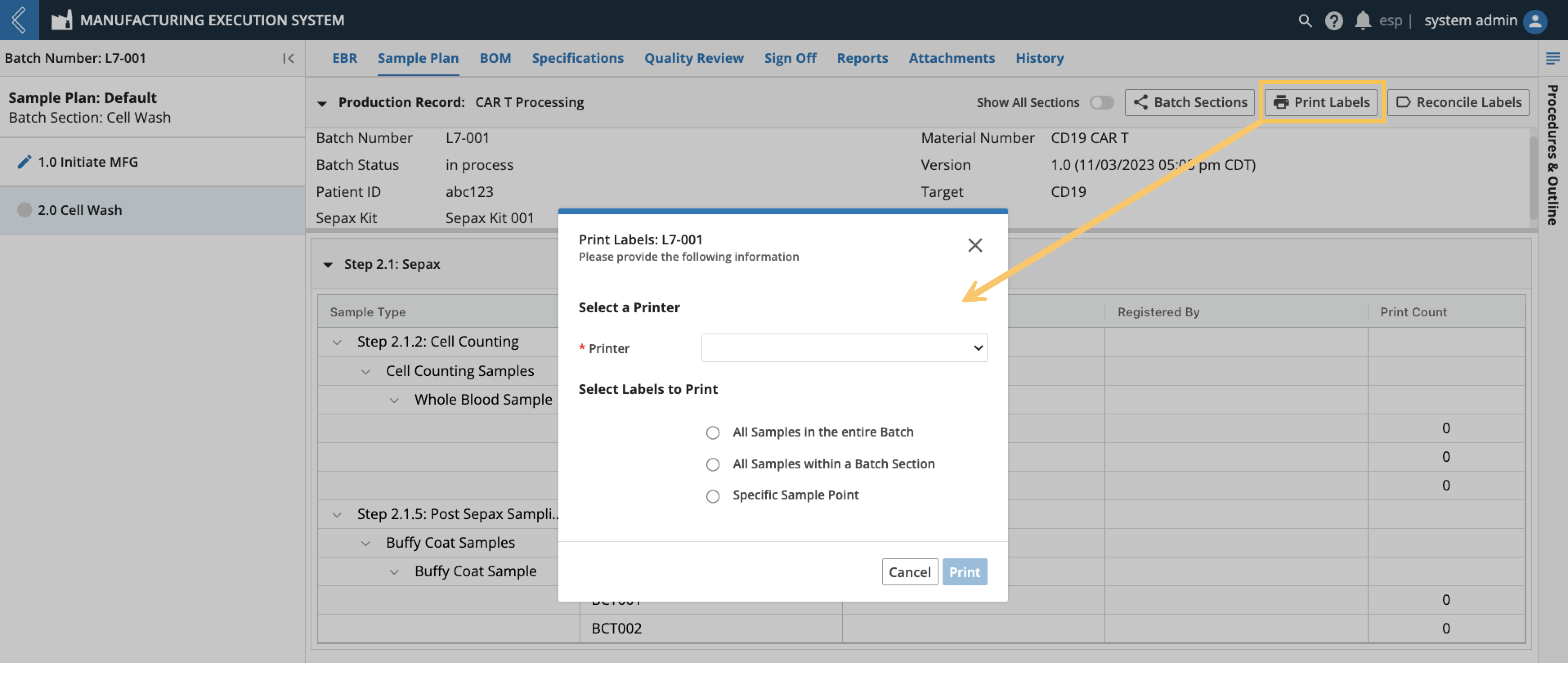

During Batch creation, L7 MES reserves Sample IDs so that labels can be printed for use in the Batch. These labels are typically attached to the Sample and scanned during production to complete registration.

Labels can be printed at any time during processing, but the Planner typically prints them before Batch processing begins.

Follow the steps below to print Sample labels.

Go to the Sample Plan tab

Click Print Labels at the top of the tab

Select a Printer

Select the labels to print:

All samples in the entire Batch – print one (1) label for every Sample ID reserved for the entire Batch

All samples within a Batch Section – print one (1) label for every Sample ID reserved in the selected Batch Section

Specific Sample Point – print one (1) label for every Sample ID reserved in the selected Sample Point

Click Print

|

If printing is successful, the Print Count for each label is incremented.

|