Dynamic Execution Plans (DEPs)

Goals

Understand how Dynamic Execution Plans are used in MES

Know how to create new Dynamic Execution Plans

Key Terms

Term | Definition |

|---|---|

Dynamic Execution Plan (DEP) | DEPs are process plans that provide alternative parameters for procedural Steps belonging to a specific Recipe (Workflow Chain). DEPs consist of Sample and Specification Plans. |

Sample Plan | A specific type of plan that enables you to modify the Sample Points in a Recipe without changing the underlying process Steps. |

Specification Plan | A specific type of plan that enables you to modify the Specifications in a Recipe without changing the underlying process Steps. |

What are DEPs and when do you use them in MES?

DEPs are process plans that provide alternative parameters for procedural Steps belonging to a specific Recipe (Workflow Chain). Sample Points can be edited to create Sample Plans, and Specifications can be adjusted to create Specification Plans.

Example Use Cases

Use-case 1: Specifications – manufacturing the same biologics agent for different countries

The process is identical, but different countries may have different regulations that necessitate different allowed tolerances on certain QC values as well as different output values. For instance, the minimum and maximum dose size of a drug may be different for different countries, so for some countries the “50mg” tablet may be manufactured, with its corresponding tolerances, and for others the “80mg” tablet may be manufactured with a different set of tolerances. Having to maintain duplicate copies of the Workflow Chain, Workflows, and Protocols for both countries is not sustainable. Instead, having a single process definition but different parameterizations of the process is ideal. This could involve making changes to:

Default values (including with expressions)

Numeric tolerances (min/max/soft)

Whether a field is required

Whether a field is read-only

Whether a field is visible

Use-case 2: Sample Points – changing Sample Plans for stability studies

When creating a new Product, stability studies are required for many industries to understand how a Product’s efficacy changes over time and in different storage conditions. Typically, samples for a stability study are collected during normal manufacturing runs, but the number of samples taken may vary from run to run, eventually tapering off to zero. Having to review the Protocol versions for all Protocols in the process each manufacturing run is not sustainable. Instead, a DEP specific to L7|ESP “Sample Point” fields can be created that allows for overriding:

The types of samples to pull

The min/max number of each type of sample to pull

The global min/max number of samples to pull

How does an End User interact with DEPs?

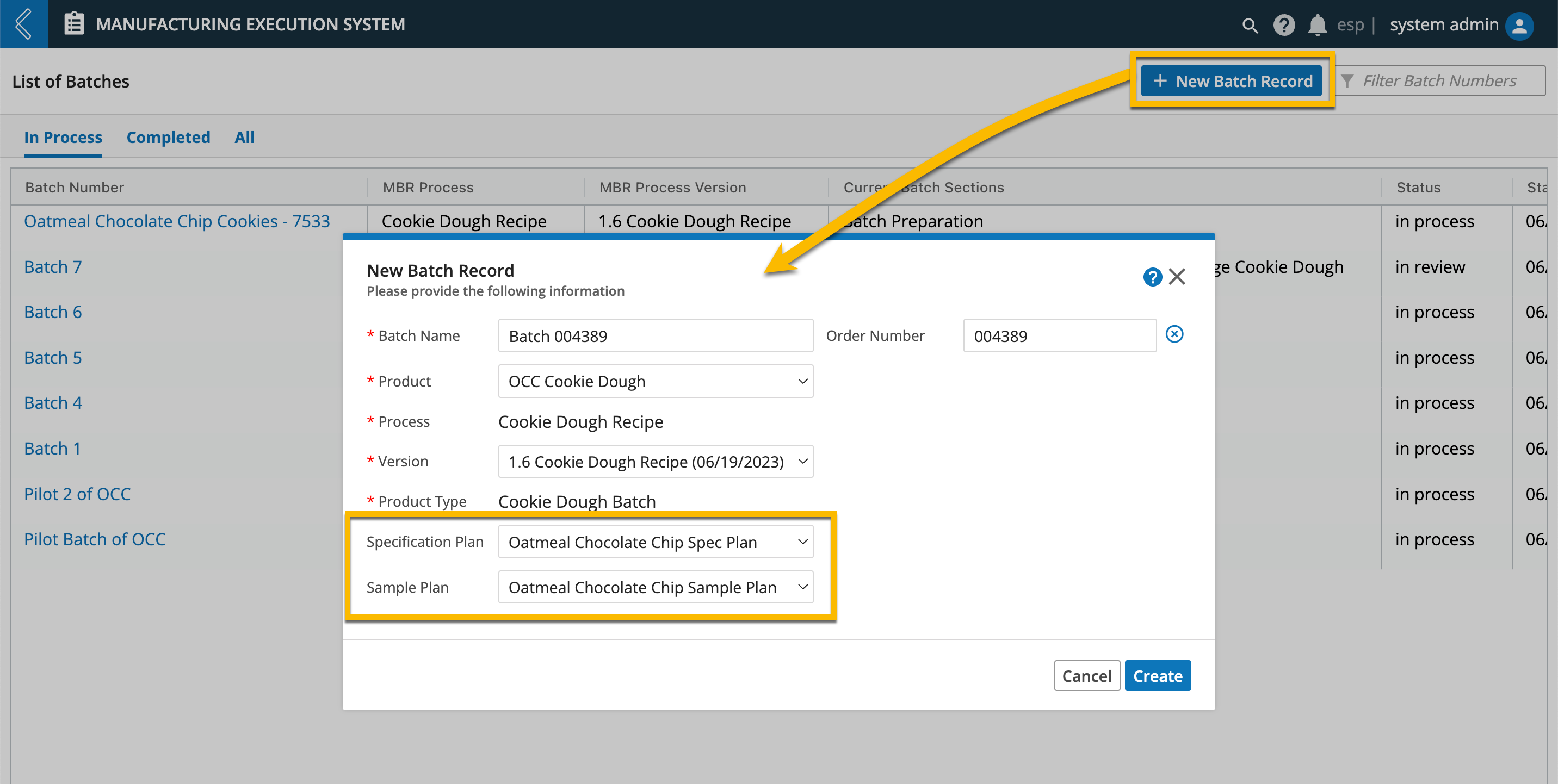

When Users create a new Batch Record in MES, they are prompted to select a Specification Plan and a Sample Plan for the process (Recipe). Both of these plans are types of DEPs that get modeled by Super Users in L7|Master.

Note

To see which Sample and Specification Plans were selected when the Batch was created, go to the Sample Plan tab and Specifications tab, respectively. The name of the plan will appear at the top of the collapsable panel on the left-hand of the page. If no plan was selected, it will say “Default”.

How to model DEPs

To create a new DEP:

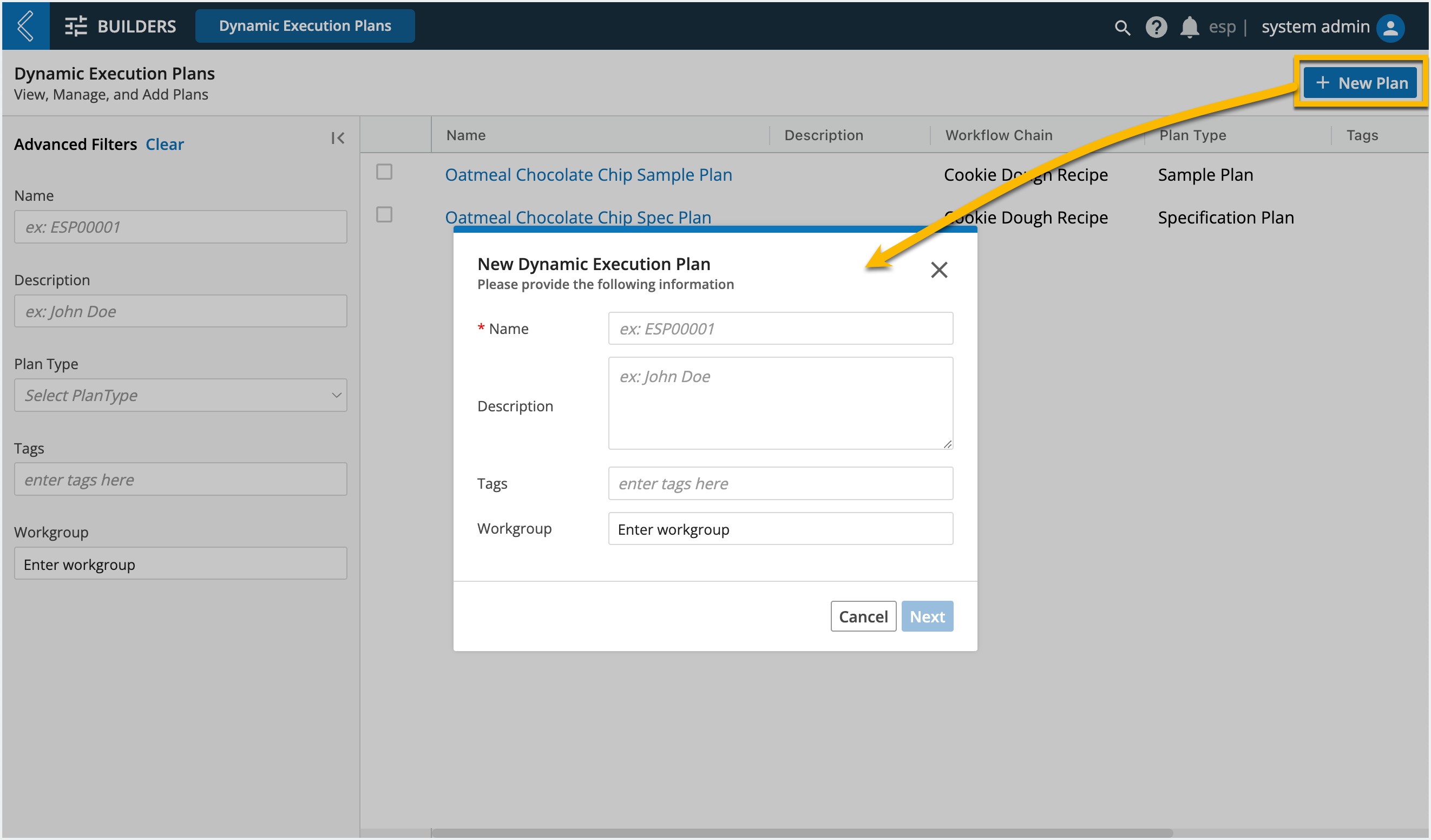

Go to: Builders (L7|Master) → Dynamic Execution Plan

Select + New Plan

Enter a unique Name (the remaining fields are optional)

Next

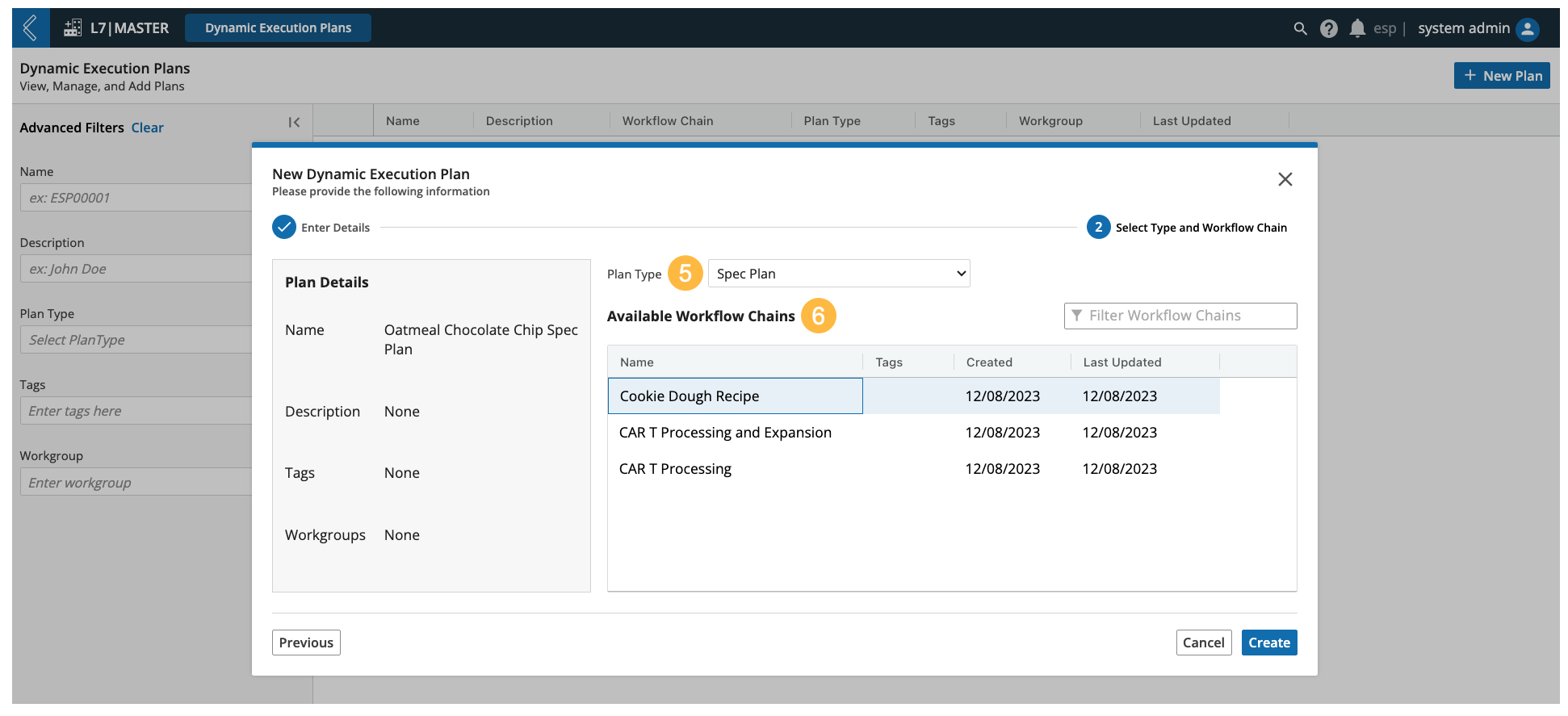

5. Select the Plan Type: Specification Plan or Sample Plan.

6. Select the Workflow Chain that the plan will be associated with.

7. Create

|

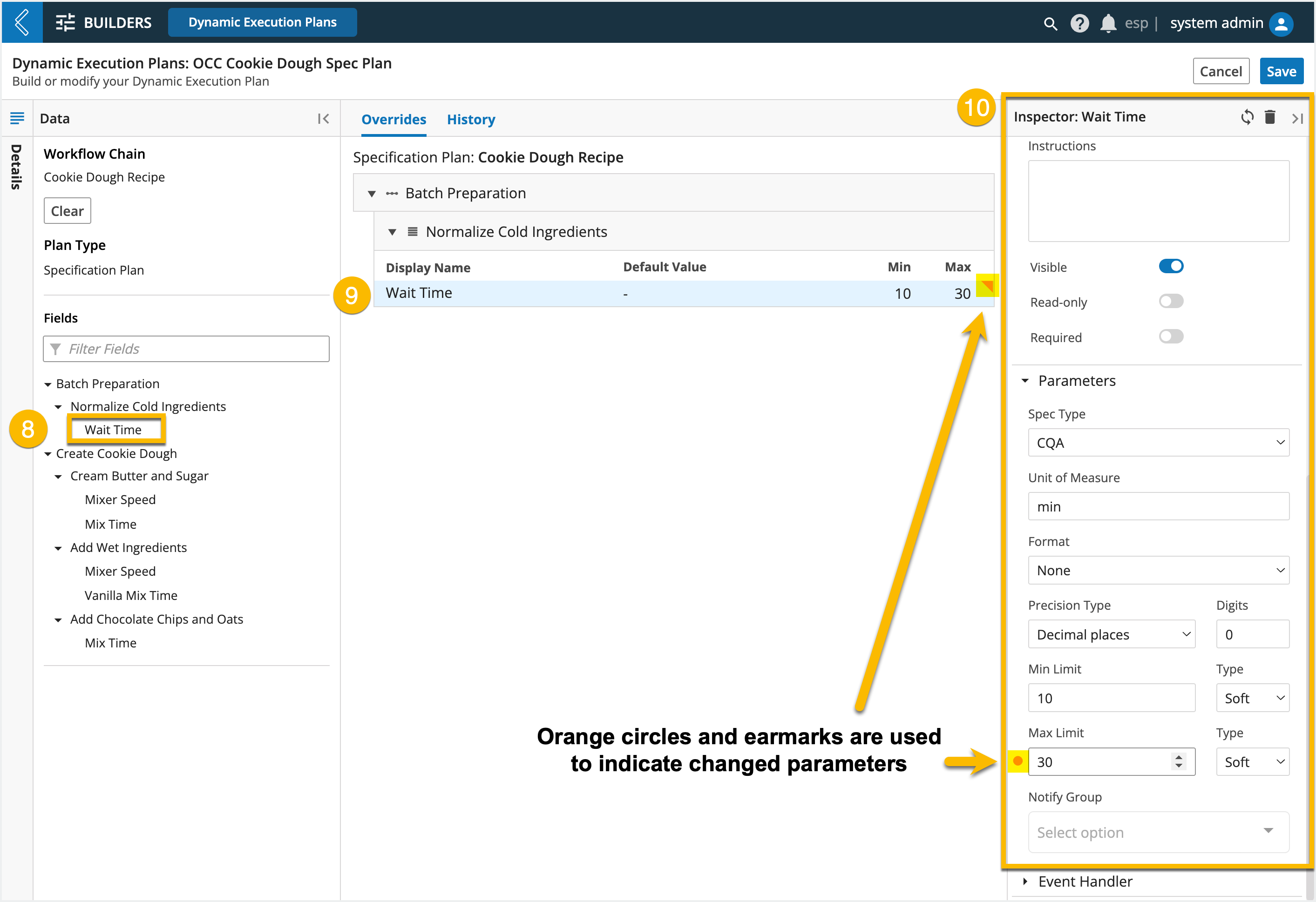

Lastly, define how the execution plan will override the default fields. Notice that the Data panel displays all the fields in the Workflow Chain that match the chosen Plan Type.

Select the desired field in the Data panel (organized by Workflow → Protocol → field). This will display the field in the Overrides tab.

Select the desired field in the Overrides tab, this will populate the Inspector panel.

Modify the field’s parameters as desired. Once a parameter has been modified, an orange circle will appear next to it, and in the Overrides tab the field will have an orange earmark indicator.

Save

Repeat steps 8-11 for the remaining fields that need to be modified for the plan.

Note

DEPs cannot override a field’s ID, Type, Var Group or Event Handler.

At this time, DEPs are only supported in MES.

Note

If you want to restrict who has access to the DEP, expand the Details panel (to the left of the Data panel), then select the desired Workgroup(s).