Exercise 6: Creating Kits and Storage Locations

Reference Material

Exercise Objectives

Part 1: Create two (2) new Container Types in L7|Master

Part 2: Create two (2) new Containers in the Location app

Part 3: Fill the Sepax Kit

Scenario

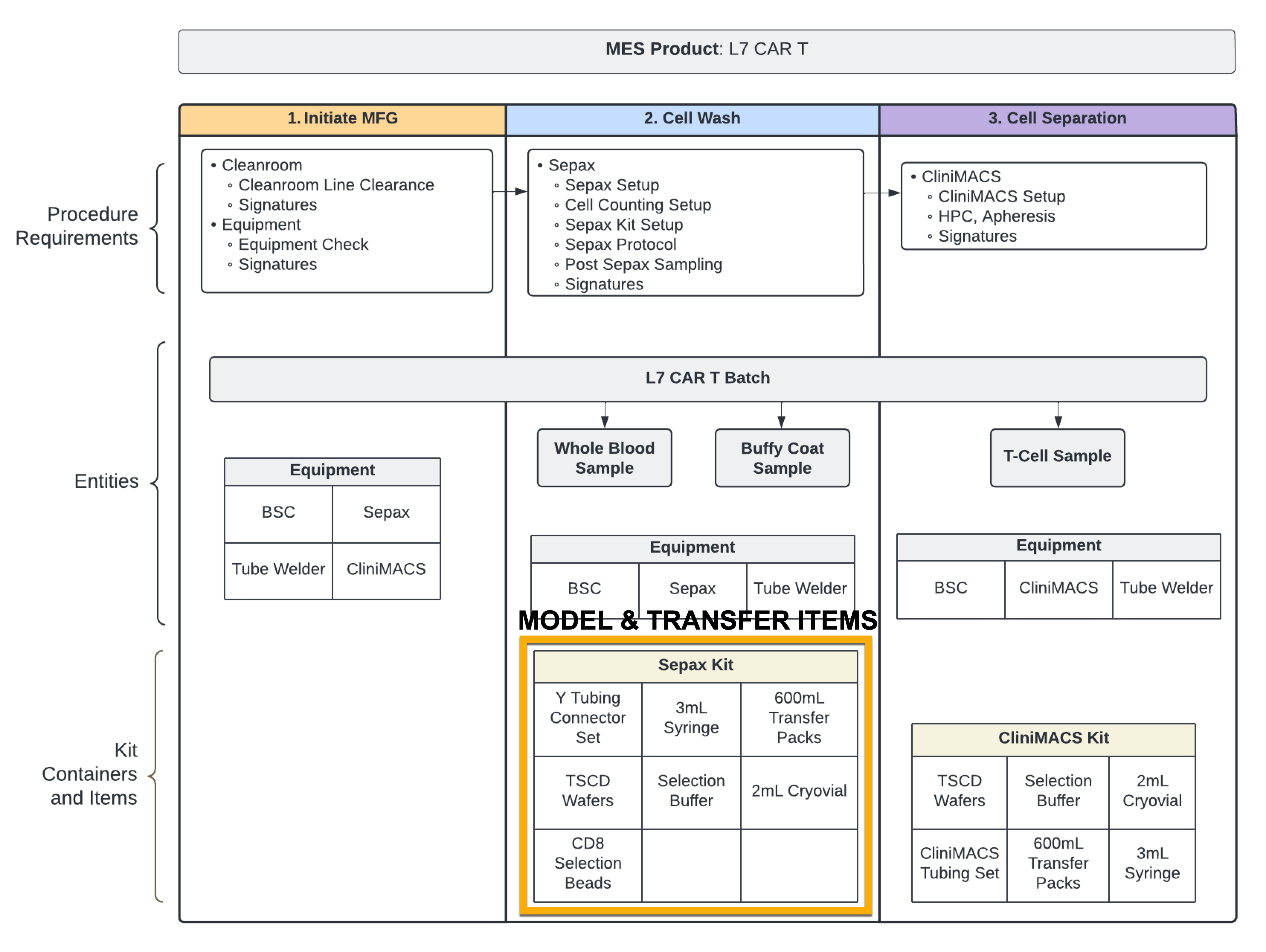

In manufacturing, inventory items are packaged into kits. These kits can correspond to the process, or a component of the process. In CAR T Processing, each kit corresponds to a component of the process:

Sepax Kit - cell washing

CliniMACS Kit - cell separation

In this exercise, you will be modeling the Sepax Kit and a Liquid Nitrogen Tank for long-term storage.

Your Task

Part 1: As a Super User, you have been asked to create two (2) new Container Types.

Manufacturing Operations has provided the following requirements:

Sepax Kit

The Kit has a single dimension labeled numerically

The Kit can store multiple Items at specified quantities:

3 mL Syringe

min: 1

max: 2

600 mL Transfer Packs

min: 1

max: 2

CD8 Selection Beads

min: 2

max: 4

2 mL Cryovial

min: 1

max: 2

Selection Buffer

min: 2

max: 4

TSCD Wafers

min: 5

max: 10

Y Tubing Connector Set

min: 1

max: 2

Liquid Nitrogen (LN2) Tank used to store Racks

Four (4) Quadrants

Each Quadrant can store multiple LN2 Racks

The labels should read Quadrant 1, Quadrant 2, etc.

Part 2: Navigate to the Location app and create one (1) new Sepax Kit and one (1) new LN2 Tank. Do not assign a status to the Sepax Kit.

Tip

When testing your Container configurations, pay attention to:

Are your Containers configured correctly?

Do they have the right number of dimensions?

Are the dimensions labeled correctly?

What can be stored in the LN2 Tank?

Does the Sepax Kit have Item Type and quantity restrictions? How do you know?

Part 3: Transfer the max quantity of each Item Type in Part 2 to the Sepax Kit in the Location app.

Note

Additional work will be done with the LN2 Tank in the Capstone Project on Day 4.